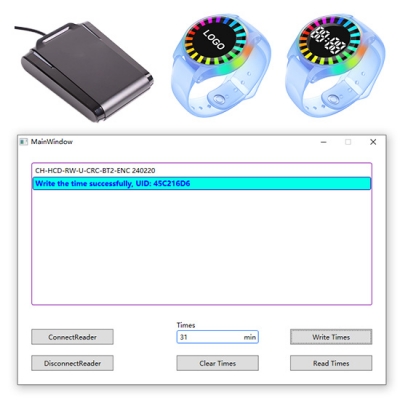

Radio Frequency Identification (RFID) technology has become an integral part of various industries, especially in healthcare, logistics, and event management. RFID wristbands are widely used for patient identification, access control, and event tracking.

Medical devices, equipment, and even patient identification wristbands must be sterilized to ensure patient safety. Autoclave sterilization is one of the most commonly used sterilization methods in healthcare. This has led to discussions about the durability and functionality of RFID tags in processes such as autoclave sterilization.

RFID Tags Compatibility with Autoclaves

The material used in RFID tags plays an important role in their ability to withstand autoclave sterilization. Common materials include:

Plastic: Many RFID tags are encapsulated in plastic materials, which may not be able to withstand high temperatures.

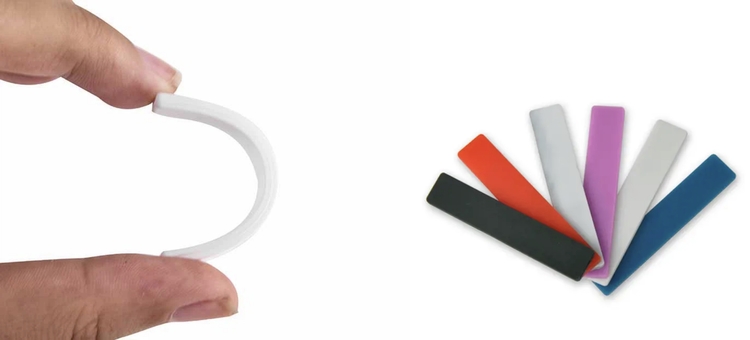

Silicone: Some RFID tags are made of silicone, which can withstand higher temperatures and is more flexible. For example, "Heat-Resistant UHF Soft RFID Silicone Tags", these tags are waterproof and corrosion-resistant, and can maintain stable performance and stability even under temperature fluctuations.

Ceramic: Ceramic RFID tags are often used in applications that require high temperature resistance and are well suited for autoclaving.

Studies have found that wristbands made from silicone and ceramic materials were able to maintain their functionality, while wristbands made from standard plastics showed signs of performance degradation and reduced signal strength. This highlights the importance of choosing the right material, such as that used in the "Custom Silicone Bracket Adjustable ID Wristband". Made from 100% silicone, these wristbands are durable, heat-resistant, highly flexible, and waterproof, making them suitable for a variety of applications, including healthcare settings.

consider the following recommendations:

Choose the right material: Choose RFID tags made from materials that can withstand high temperatures and autoclaves.

Perform pre- and post-sterilization testing: Regularly test RFID tags before and after autoclaving to ensure they are functioning properly.

Implement proper operating procedures: Train employees to properly handle and sterilize RFID wristbands to minimize damage.

Consider Alternative Sterilization Methods: Explore alternative sterilization methods, such as ethylene oxide or hydrogen peroxide gas plasma sterilization, which may be less damaging to RFID tags.

Future Trends in RFID Technology and Sterilization

As the demand for RFID technology continues to grow, researchers and manufacturers are exploring new materials that can withstand extreme conditions. Innovations in biocompatible materials, heat-resistant polymers, and advanced coatings are expected to advance the development of RFID tags that can withstand autoclave sterilization without compromising their functionality.

Conclusion

The compatibility of RFID tags with sterilization processes such as autoclave is a key consideration. While many RFID tags can withstand autoclave sterilization, the choice of materials and design can significantly affect their post-sterilization performance.

As the healthcare industry continues to prioritize infection control and patient safety, understanding the interaction between RFID technology and sterilization processes is critical to ensuring the reliability and functionality of these systems. Future research and development should focus on developing more robust RFID solutions that can withstand rigorous sterilization methods while maintaining their operational integrity.