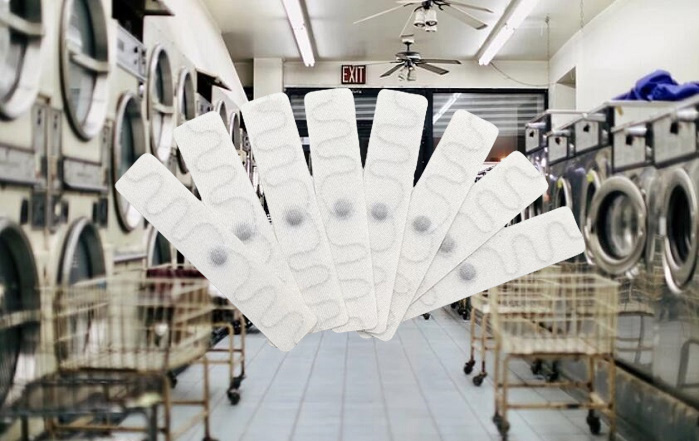

In an age where the fabric laundry industry is constantly striving for optimisation, traditional methods of garment inventory management often seem overwhelming. Lost or misplaced garments, inefficient supply chains, and labour-intensive inventory processes can pose significant challenges. It is possible to automate washing, sorting, tracking and inventory management to improve efficiency and accuracy throughout the laundry supply chain.

The Power of UHF Washable RFID Tags

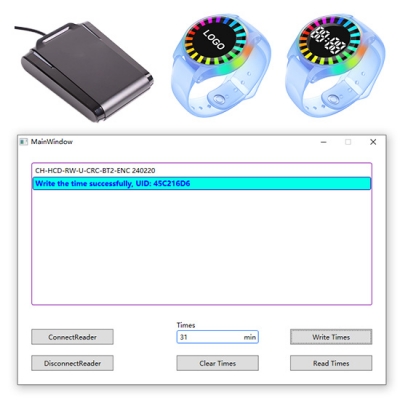

UHF (Ultra-High Frequency) washable RFID tags are specifically designed to withstand washing and drying processes, making them an ideal choice for garment tracking. With robust waterproof, wash resistance, and high-temperature durability, these UHF tags outperform traditional barcodes by allowing remote reading without physical contact. Consequently, the reading speed and convenience are significantly enhanced, streamlining inventory management across multiple locations.

The laundry industry, including hotels, hospitals, guesthouses, and dry-cleaners, extensively employs UHF washable RFID tags. Leveraging tag identification and management, it enables automated processes such as washing, sorting, tracking, and inventory management. This integration enhances the overall efficiency and accuracy of the entire laundry supply chain.

Incorporating RFID Tags in Clothing

Waterproof RFID laundry tags are typically sewn into garments, enabling information to be read at each stage of the washing process while effectively managing uniforms and clothing items. RFID readers need to be strategically placed at various checkpoints, including receiving, sorting, washing, drying, ironing, folding, categorizing, transportation, and distribution. These tags are specifically engineered to withstand chemicals used in the washing process and endure high temperatures during washing, drying, and ironing.

Real-Time Accuracy and Tracking

RFID washable tags employ radio frequency identification technology to promptly and accurately identify and track each garment in real time. By embedding the tags into clothing, laundry facilities or end-users can effortlessly identify and track individual items, minimizing the risk of loss or mix-up. This technology revolutionizes inventory management, optimizing stock control and ensuring the availability of clean and properly maintained garments.

Meihe, with over 20 years of experience in the RFID industry, we offer a wide range of RFID laundry tags in a variety of materials designed to meet your specific requirements. Examples include RFID textile laundry tags, RFID PPS button laundry tags, RFID silicone laundry tags, and more. By choosing the right tag, you can optimise your laundry management system and increase productivity and customer satisfaction.