Under this background, it is urgent to strengthen the government safety supervision of liquefied petroleum gas cylinders, implement the policy of cylinder construction, fixed-point filling, and regular inspection, and establish a networked dynamic gas cylinder safety management system.

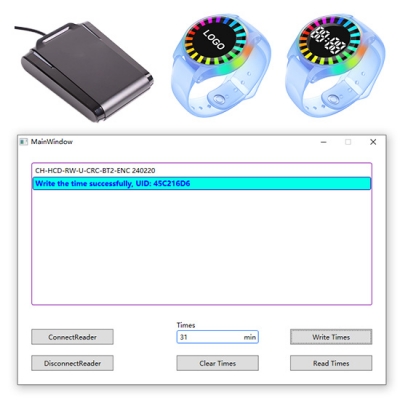

RFID technology has played a key role in this management system. Through RFID technology, the identity of the gas cylinder can be quickly and accurately identified, the production efficiency can be improved, and the gas cylinder to be inspected can be prevented from flowing into the production process, resulting in quality hazards.

The specific implementation process:

1. First, establish a computer resume file database of gas cylinders.

2. The RFID hand-held machine is used to read the electronic label of the gas cylinder, and the on-site operation data of the process of sending and receiving the gas cylinder, pre-charge inspection, filling and filling, re-inspection, and periodic inspection are collected and registered.

3. Alarms and prompts for abnormal and bad cylinders.

4. At the gas station, register the gas cylinders entering and leaving the gas supply station to prevent other gas cylinders from entering the enterprise through the gas station channel.

What problems does RFID technology solve?

1. Solve the problem that the number of cylinders in the jurisdiction is unknown by the regulatory authorities and the filling unit.

2. Improve work efficiency, greatly reduce labor intensity, and increase the enthusiasm of employees.

3. Realized the computer dynamic management of the safety status of the cylinders in the jurisdiction.

4. Improve the accuracy and accuracy of the data.

5. Improve the anti-counterfeiting of electronic tags and greatly improve the inspection rate.

6, the realization of the data sharing of various management departments.

7, is conducive to the realization of paperless office, saving office costs.

8. Eliminate the violation of the regulations that the filling unit does not register or the property rights are not in the unit.

This program implements a one-of-a-kind, one-bottle, one-track retrospective management by establishing a permanent “RFID ID card” for gas cylinders. It completely changed the phenomenon of low-level and unsafe operation of the original on-site operator labor, time-consuming, naked-eye identification and manual recording.