The RFID power inspection system is composed of on-site power equipment and card issuing equipment, electronic tags, mobile data collection terminals and application systems that need to be inspected.

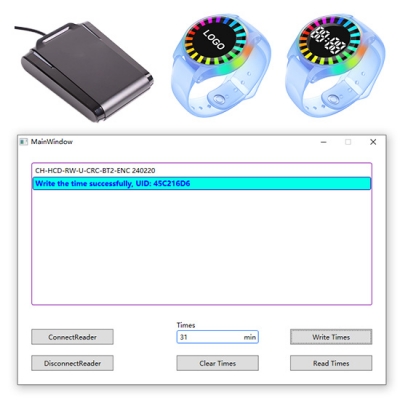

(1) The card issuing device mainly completes the data initialization of the electronic tag, and writes the specific asset code and other information of the power company into the electronic tag;

(2) Electronic tags are used to store detailed data information and historical verification information of the equipment;

(3) The mobile data acquisition terminal is a tool for patrol operation. It can patrol the designated equipment of the designated unit according to the tasks downloaded from the PC application, record the patrol results, and then transmit the field data to the PC through the wireless communication network. Machine background management system;

(4) The device application server is responsible for operations such as customer management and data sorting, and interacts with the database server;

(5) The database server is responsible for storing the basic data and parameter information of the power equipment, the query and statistics of the RFID electronic tag information, and the user management, help and other information.

Card issuance is to complete the initialization of electronic label information and establish basic data. Because power equipment is mostly made of metal, the electronic tag used in this solution is an anti-metal tag. This type of label is different from the general Inlay label, which can be printed directly by an RFID printer. As a special-shaped label, it can only be issued one by one through an RFID card issuer. The RFID card issuer with group write card function will greatly mention the card issuing efficiency in this link, and it is especially suitable for special-shaped tags such as anti-metal.

3.2.2 Inspection

When the inspectors carry the mobile data collection terminal and go out for inspections, they read the electronic tags through the mobile receipt collection terminal to obtain equipment-related information, and take pictures of the equipment according to the situation, while recording the operation of the equipment and the execution of the characters. If a fault is found, the current mobile data collection terminal will send the fault type, equipment number and other information to the background management system.

The back-end management system reads and stores the information sent back from the mobile data collection terminal, breaks down the time, location, equipment type, and discoverer of the fault, and automatically stores this information in the database server and publishes it online. In addition, the system displays the inspection status in real time, such as displaying various fault points, emergency situations, handling conditions, current status of various faults, as well as the location and inspection route of each inspector at a certain time. The system can also perform statistics, summary, and analysis of various historical data stored in the database, and use various charts or reports to display the frequency and objects of various faults within a certain period of time, for management personnel to predict and analyze to strengthen management and Formulate countermeasures to achieve the purpose of prior control, ultimately reduce the accident rate, and ensure the safe operation of power equipment.

3.3 Implementation benefits

The electric power inspection system based on RFID technology will be able to solve the problems of electric power enterprises in the inspection and inspection, and bring tangible benefits to the enterprise, which are mainly reflected in the following aspects:

A. It is convenient for inspectors to conduct inspections and submit inspection results, reducing the chance of human error;

B. Ensure that the inspection personnel are in place, and ensure the inspection quality and management efficiency of the inspection work;

C. The quality and efficiency of patrol inspection are greatly improved, which guarantees the stable operation of transmission equipment, prevents problems before they occur, reduces the incidence of failures, and reduces the operating costs of enterprises;

D. Improved data analysis and statistical functions, and improved the efficiency of management personnel in dealing with defects.

Anti-metal RFID tags are embedded with a sheet of ferrite that is placed between the RFID tagand the adhesive backing of the tag