In the modern world, efficient asset tracking is crucial for businesses to streamline operations and ensure optimal resource management. The advent of radio frequency identification (RFID) technology has challenged the traditional dominance of barcodes in asset tracking. While barcodes have long been the default choice due to their simplicity, affordability, and accuracy, RFID offers a range of advantages that address the limitations of barcode-based systems. Now, we will explore the merits of both RFID and barcode technologies to determine which one is best suited for effective asset tracking.

Barcode Technology

Before the rise of RFID, barcodes served as the go-to technology for asset management and inventory tracking. Barcodes are easy to use, inexpensive, and deliver high levels of accuracy, which explains their widespread popularity. However, there are certain drawbacks associated with using barcodes for asset tracking:

● Line of Sight Requirement: Barcodes require direct visibility during scanning, meaning they must be within the line of sight of the scanner. This limitation can slow down the tracking process, especially for assets located in challenging or inaccessible positions.

●Vulnerability to Damage: Barcodes are susceptible to physical wear and tear, making them prone to damage and rendering them ineffective. Exposure to moisture, heat, or scratching can compromise their legibility, hindering accurate tracking.

●Single Scan Capability: With barcodes, only one tag can be scanned at a time. This can be time-consuming and impractical when dealing with a large number of assets, leading to inefficiencies in tracking operations.

●Limited Data Storage: Barcodes can only store a small amount of data. 1D barcodes, the most common variant, can accommodate only 8-25 characters. This limitation restricts the level of information that can be associated with each asset, potentially hindering comprehensive asset management.

● Read-Only Functionality: Barcodes are read-only, meaning they lack the ability to update or modify data once printed. This limitation can be problematic when real-time asset tracking or dynamic information updates are required.

RFID Technology

RFID technology provides numerous advantages over barcode systems, making it an increasingly popular choice for asset tracking:

◆Non-Line of Sight Operation: RFID does not rely on direct line of sight for scanning. Instead, it employs radio waves to communicate between the tags and readers. This enables scanning and tracking of assets even when they are obstructed or enclosed within containers or packages, enhancing operational efficiency.

◆Durability: RFID tags are more robust and durable compared to barcodes. They are designed to withstand harsh environments, such as extreme temperatures or exposure to chemicals, ensuring reliable performance throughout the asset's lifecycle.

◆Multiple Tag Scanning: RFID readers can simultaneously scan multiple tags within their range. This capability significantly speeds up the tracking process and simplifies inventory management, making it ideal for high-volume asset tracking scenarios.

◆Extensive Data Storage: RFID tags can store a wealth of information, including unique identifiers, specifications, maintenance history, and much more. This comprehensive data storage capability enables businesses to efficiently track and manage assets while providing rich contextual information about each item.

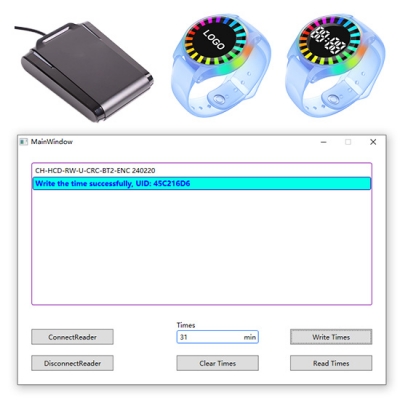

◆Read-Write Functionality: Unlike barcodes, RFID technology allows for read-write functionality, enabling the modification and updating of data stored on the tags. This feature is particularly valuable for real-time tracking, dynamic inventory management, and asset maintenance purposes.