RFID cards are widely used for identification, tracking, and data storage. These cards contain an embedded chip and antenna that enable wireless communication with RFID readers. The material choice for RFID cards is crucial, as it impacts the card's durability, performance, and application suitability. This article explores the materials used in RFID card manufacturing and their respective applications.

PVC: The Standard Material for RFID Cards

PVC is the most commonly used material for RFID cards due to its affordability, durability, and ease of customization. It is widely used in access control systems, public transportation cards, and employee ID cards. PVC cards can withstand temperatures ranging from -20°C to 60°C, making them suitable for most environments. PVC also supports a variety of design techniques. For example, for those seeking a high-end touch, Meihe "Specially Processed PVC Laser Cards" offer an unparalleled, elegant appearance. These cards feature exquisite graphics and vibrant designs, along with advanced finishes such as matte, glossy, or UV coatings, making them ideal for VIP memberships and exclusive clubs.

PET: Environmentally Friendly and Durable

PET is a sustainable alternative to PVC, offering similar durability and flexibility. Biodegradable and recyclable, PET RFID cards are ideal for environmentally conscious organizations. PET RFID cards are commonly used for membership programs and event tickets. A notable example is Meihe's eco-friendly product, biodegradable PETG plastic cards, which combine high transparency, chemical resistance, and full recyclability. PETG decomposes into carbon dioxide and water, making it a safe and sustainable choice for a variety of applications.

ABS: Industrial-Grade High Durability

ABS is a tough thermoplastic material known for its impact resistance and mechanical strength. RFID cards made from ABS are suitable for harsh industrial environments, such as manufacturing plants and construction sites. These cards can withstand extreme temperatures and physical pressure, ensuring long-term reliability.

Polycarbonate: Enhanced Security

Polycarbonate is a premium material for RFID cards, offering exceptional durability and tamper-resistant properties. It is commonly used in high-security applications such as government ID cards and passports. Polycarbonate cards can withstand extreme temperatures, chemical exposure, and physical wear, making them ideal for long-term use. US ePassports utilize polycarbonate RFID technology for enhanced security.

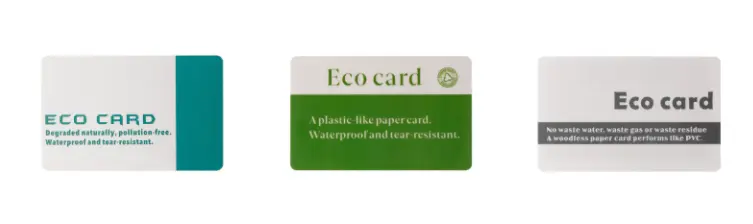

Paper RFID Cards: Affordable and Disposable

Paper RFID cards are lightweight, affordable, and disposable, making them ideal for short-term applications such as event tickets and promotional materials. These cards are often laminated for increased durability and can be customized through printing. However, they are not as durable as plastic cards and are not recommended for long-term use. As a more sustainable alternative to paper, RFID Eco-Friendly Bio-Paper Cards combine RFID technology with biodegradable materials. These cards decompose under the right conditions, providing an environmentally friendly solution for temporary applications.

Metal-Compatible RFID Cards: Special Applications

Metal-compatible RFID cards are designed to operate in environments with metal interference. They utilize specialized materials such as ferrites or shielding layers to ensure reliable performance. These cards are used in industries such as aerospace and automotive, where metal components are prevalent.

Biodegradable Materials: The Future of RFID Cards

With growing environmental awareness, biodegradable materials such as PLA are becoming increasingly popular in RFID card manufacturing. PLA is derived from renewable resources such as corn starch and is fully compostable. Although the application of PLA-based RFID cards is still in its infancy, it is expected that they will be more widely used in the field of environmental protection.

Conclusion: Choosing the Right Material

The choice of RFID card material depends on factors such as durability, safety, and environmental impact. PVC remains the standard choice for general applications, while specialized materials such as polycarbonate and ABS meet high-security and industrial requirements. As sustainability becomes a priority, biodegradable materials such as PETG and PLA are emerging as viable alternatives. Understanding these materials and their applications can help organizations make informed decisions about their RFID card needs.