Currently, the tools commonly used to manage item numbers are usually barcodes and QR codes. However, due to size limitations, the existing methods are subject to many restrictions when trying to control a large number of small hospital equipment. In addition, the hospital environment is relatively harsh, and it is necessary to face changes in temperature and pressure, and it is easy to be stained. In addition, some labels can no longer be tracked after the product is sold, which makes the application of traditional methods in the hospital environment challenging. In response to the complex application environment of the hospital, Meihe provides micro ceramic high temperature resistant anti-metal labels.

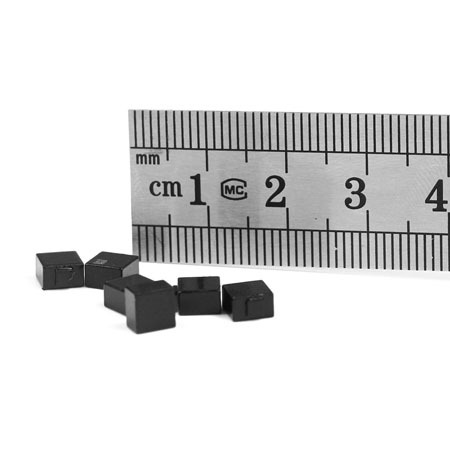

Micro ceramic high temperature resistant anti-metal tag, despite its tiny size of 5x5x3mm, its unique antenna design enables its effective reading distance to reach 1 meter. The shell is encapsulated with ceramic material, which can ensure that the tag can be used normally in harsh environments such as high temperature, high pressure, chemical corrosion, etc. It is a popular high temperature and corrosion resistant tag. Micro ceramic high temperature resistant anti-metal tag can be embedded in metal grooves and widely used in RFID radio frequency fields such as medical equipment, small tool management, tool inventory, firearms, metal accessories, embedded mold management, etc.

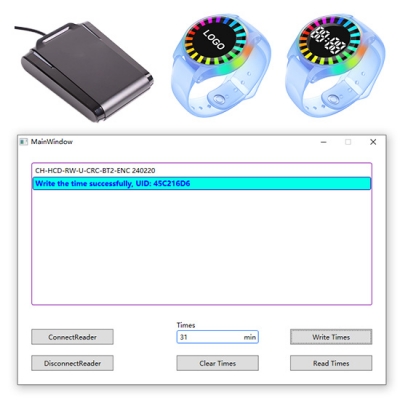

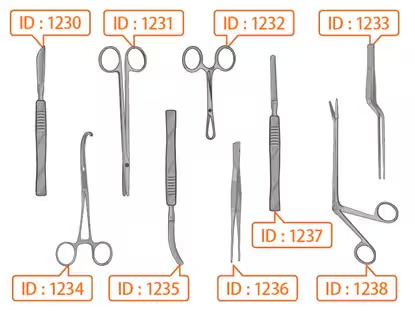

In addition to being a unique ID, the micro ceramic heat resistant anti-metal tag can also record the use time and service life of surgical tools, making management easier, and can be quickly read in batches, allowing operators to efficiently assemble and check the entire set of tools. In addition, the number of times each tool is used can be recorded to reduce excessive inventory, and the order of use can be recorded to optimize the preparation of preoperative tools.

After surgical tools are used, micro ceramic heat resistance anti-metal tags can be used for efficient inventory counting and usage time management. They can be read in batches and quickly managed. Even if the staff is stained with blood after surgery, they can still read the information of the micro ceramic high temperature resistant anti-metal tags. Therefore, it is an ideal choice for surgical tool management.

A large number of medical instruments are also used in hospitals. The use of micro ceramic high temperature resistant anti-metal tags to authenticate medical instruments will improve the efficiency and safety of medical care. Micro ceramic high temperature resistant anti-metal tags help to correctly track the use records of operations or cleaning, and help replace medical equipment parts such as endoscopes, ultrasonic diagnostics, scalpels, ultrasonic coagulation and cutting equipment. In addition, more efficient operations can be achieved by automatically recording and storing RFID information.