In the medical industry or related industries, careful management of cleanroom clothing inventory is a key link to ensure uninterrupted production operations. Adjustments in production schedules and fluctuations in employee rest frequencies pose challenges to daily clothing demand estimations. Each time an employee exits and re-enters a cleanroom facility, a change of new cleanroom attire is necessitated. Failure to equip employees exiting clean areas with fresh garments impairs their re-entry, directly impacting production.

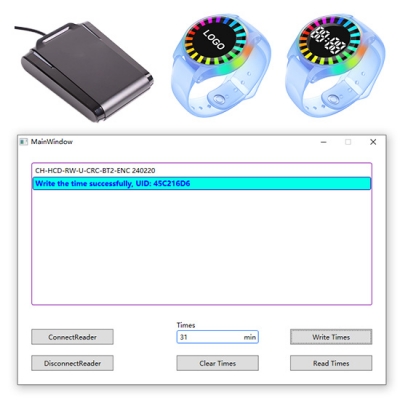

The advent of RFID technology has ushered in an era of efficient, reliable, and fully traceable transformation in cleanroom garment management. Notably, the integration of RFID washable laundry tag has streamlined processes, mitigated human errors, and advanced modernized, compliance-driven management practices. RFID wash labels afford a precise monitoring method for garment usage patterns, with each attire featuring a preset lifecycle embedded in an RFID chip dictating maximum wash and sterilization frequencies. Automated RFID readers confirm garment compliance within their specified lifecycles, promptly flagging and removing any non-compliant garments from circulation. Prior to the introduction of RFID laundry tags, these tracking endeavors were laboriously manual, significantly heightening the risk of human error.

Moreover, leveraging RFID systems for data analytics and imparting usage recommendations aids in optimizing inventory management. This not only curtails stockpile build-ups or shortages but also guarantees the availability of cleanroom garments at all times, minimizes wastage, and averts production delays stemming from clean garment scarcity.

Furthermore, by means of tracking laundry RFID tags, a comprehensive understanding of each cleanroom garment's entire lifecycle—from washing through delivery to utilization—is made possible. This delineation of detailed information, encompassing wash cycles, delivery logs, and usage timelines, is instrumental in addressing queries raised by auditors or regulatory bodies.

As the industry landscape evolves, clients are increasingly seeking holistic solutions. For instance, harnessing RFID for access control enables only authorized personnel to enter cleanroom areas or facilitates real-time monitoring of cleanroom environments to ensure that environmental conditions and personnel limits remain uncompromised. We are firm believers in the limitless potentials for RFID technology to continue advancing and meeting diverse customer demands.