From thin paper tags to sturdy hard tags, RFID technology is used in almost every industry. It is used in transportation, food safety, animal identification, financial payments, logistics, retail, manufacturing, apparel, healthcare, security, asset management, and even military and aviation.

The breadth of these applications means that billions of RFID tags are deployed worldwide each year. This huge number raises a key question: What impact does such a large amount of tag use have on the environment? And how can it be managed?

For many years, many RFID tags, especially in the retail industry, were considered disposable. A paper tag on a T-shirt was discarded after it had served its purpose. But as RFID technology matured and its applications in industry, logistics, and asset management have become more pressing, both from an economic and environmental perspective.

Today, the focus has shifted to reusability. By extending the life of tags, companies can reduce costs and significantly reduce e-waste.

1.Understanding Reusable RFID Tags

The reusability of an RFID tag depends on two factors: its storage type and physical durability.

What types of RFID tags are suitable for reuse?

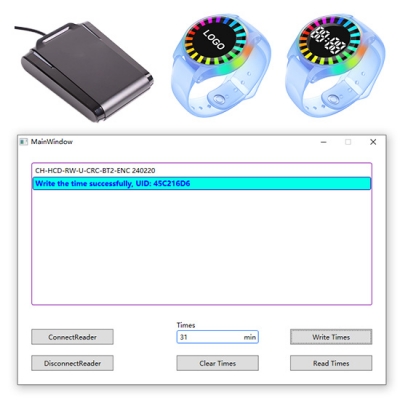

Tags used in closed-loop systems are preferred. This includes hard-shell tags that are bolted to reusable plastic boxes, pallets or barrels. These assets are designed to be easily recovered, processed and reissued. This also applies to IT asset tracking, such as transferring tags from scrapped laptops to new ones, and tool tracking, where these tags must be used for several years in a shop environment. These applications almost always use "read/write (RW) tags", which allow data to be rewritten thousands of times.

What types of RFID tags are not suitable for reuse?

Disposable "paper tags" fall into this category. While they can effectively track consumer goods at the item level, their adhesives and fragile construction make them not reusable and are essentially disposable.

2. Challenges of reusing RFID tags

Even for tags designed for reuse, the most common failure point is physical wear and tear. A tag chip can be rewritten 100,000 times, but this feature is meaningless if the tag itself breaks down after a few uses, corrodes due to exposure to chemicals, or is damaged by high temperatures.

3. Exploration and progress in reusable RFID tags

To achieve repeated use in harsh conditions, tags must be as rugged and durable as the assets they track. Hence, "PCB RFID tags" were born. These tags are based on a rugged fiberglass substrate that is extremely resistant to impact, extreme temperatures, moisture, and chemical corrosion. This construction ensures that the physical life of the tag will eventually match the electronic life of the chip inside.

This is where experienced manufacturers like Mheihe come to the fore. As an established manufacturer of professional RFID products, Mheihe understands that tag performance must be matched by long-term durability.

Mheihe's PCB RFID tags that directly meet the challenges of reuse, with features including:

Superior durability: Built on a PCB platform, these PCB tags can withstand harsh industrial environments where standard tags may fail.

Metal-Resistant: These PCB tags operate reliably even when mounted directly on metal surfaces (a common challenge with RFID), making them ideal for tracking tools, machinery, and metal containers.

Long-Term Reliability: By ensuring PCB tags can withstand years of use, Mheihe enables businesses to take full advantage of the rewritable capabilities of RFID chips, maximizing their return on investment.

With technologies like PCB Metal-Resistant Tags, Mheihe doesn’t just sell products, they help businesses deploy more cost-effective and environmentally friendly RFID systems. They prove that a tag’s life doesn’t have to end after the first “beep” – it can be the beginning of a long-term sustainable tracking solution.