At a time when the demand for digital management is constantly upgrading, the limitations of traditional barcode scanning devices in complex scenarios are gradually emerging, and more and more industries are beginning to pay attention to more efficient information collection solutions. As a product of the combination of wireless radio frequency identification technology (RFID) and mobile terminals, the First RFID handheld device is becoming an important management tool in logistics, warehousing, manufacturing and other fields with its characteristics such as contactless reading and batch data processing.

RFID handheld devices are different from traditional barcode scanning devices. Their core advantage lies in contactless reading capabilities: there is no need to scan the product barcodes one by one, but to batch read multiple label information within the effective range, and the single reading distance can reach 0.1-10 meters (depending on the label type). This "non-visible, non-contact" working mode not only solves the recognition problems caused by barcode contamination and occlusion, but also increases data collection efficiency several times, especially suitable for scenes with dense goods and high-frequency in and out of the warehouse.

Core functions:

1. Contactless batch reading, breaking through efficiency bottleneck

2. Real-time data synchronization, building a closed loop of intelligent management

3. Multi-scenario adaptation to meet differentiated needs

1. Logistics and express delivery: smarter sorting and delivery

In the express sorting process, traditional code scanning requires manual searching for the delivery bill, which is inefficient and prone to errors; after using the RFID handheld device, you only need to put the package into the sorting basket, and the device can batch read all package labels, automatically match the sorting path, and improve the sorting efficiency by more than 50%. When delivering parcels, the device can synchronize the parcel location in real time, and the customer's receipt information is uploaded to the system in seconds to avoid disputes over lost items. The warehouse data of an e-commerce company shows that after the introduction of RFID handheld devices, the daily parcel processing volume of a single warehouse has increased by 30%, and the labor cost has decreased by 25%.

2. Supermarket retail: inventory and inventory management innovation

Traditional manual inventory requires scanning of each item, and it usually takes 2-3 days for a medium-sized supermarket to complete the inventory of the entire store; while the RFID handheld device can complete the full-store scanning within 2 hours, and the out-of-stock rate of shelf goods has been reduced by 40%. In addition, the device supports product anti-theft warning: when unchecked goods approach the exit, the system automatically triggers an alarm. With the synchronization function of the electronic price tag, it can also realize real-time update of promotional information and improve store operation efficiency.

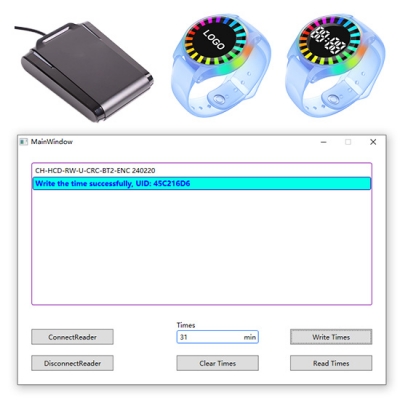

3. Healthcare: Precision nursing and consumables management

In hospital scenarios, RFID handheld devices can be used for patient wristband identification and drug consumables tracking: when nurses make rounds, they can retrieve patient medical records and medication records by scanning the wristband to avoid manual verification errors; in drug warehouses, the device automatically identifies drugs with approaching expiration dates, reminds management personnel to use them first, and reduces the waste of medical consumables. The practice of a tertiary hospital shows that after the introduction of this device, the nursing error rate has dropped by 60% and the inventory time of consumables has been shortened by 80%.

4. Manufacturing industry: production traceability and quality control

In production line management, RFID handheld devices can collect accessory information in real time, associate production processes with operators, and realize full product traceability. For example, in automobile manufacturing, the equipment reads the labels of engine parts, automatically verifies the matching degree of accessory models with orders, and prevents wrong installation or missing installation; in the warehouse, it reads raw material labels in batches, automatically generates inbound and outbound reports, and improves inventory accuracy to more than 99%.

5. Warehouse management: from "manual search for goods" to "intelligent positioning"

Traditional warehousing relies on paper documents or barcode scanning, which is time-consuming and error-prone to search for goods; RFID handheld devices combined with cargo location labels can display the location of goods in real time, support the "search for goods by map" function, and improve picking efficiency by 40%. During inventory, the equipment automatically generates a difference report, and management personnel can locate misplaced goods through the background, shortening the inventory turnover cycle by more than 20%.

Follow us and we will help you find more RFID products.